Using Microsoft Teams to Improve Collaboration in Manufacturing

In manufacturing, collaboration plays a crucial role in boosting productivity and innovation. You know how essential it is to have seamless communication and coordination among teams. Effective partnerships can lead to real-time information sharing and better risk management. Technology, especially tools like Microsoft Teams, enhances this collaboration by breaking down data silos and fostering a unified approach. By integrating modern solutions, you can transform isolated tasks into a cohesive team effort, driving efficiency and creativity. Embrace these advancements to stay ahead in the competitive manufacturing landscape.

Understanding Microsoft Teams

Overview of Microsoft Teams

Microsoft Teams serves as a central hub for teamwork within the Microsoft 365 suite. It brings together various tools and applications to enhance collaboration. You can access everything you need in one place, from instant messaging to video conferencing. This integration allows you to work efficiently without switching between different platforms.

Key features and functionalities

Microsoft Teams offers a range of features that make collaboration seamless:

Instant Messaging: Communicate quickly with team members through chat.

Audio and Video Calling: Host meetings with high-quality audio and video.

File Sharing: Share and collaborate on documents stored in OneDrive and SharePoint.

Integration with Other Apps: Connect with third-party applications to streamline workflows.

These features ensure that you have all the tools necessary for effective communication and collaboration.

Integration with Office 365

Microsoft Teams integrates seamlessly with Office 365, providing access to applications like Word, Excel, and Outlook. This integration means you can edit documents, manage emails, and schedule meetings directly within Teams. By leveraging Exchange Online, SharePoint, and Skype for Business Online, Teams ensures that your productivity tools are always at your fingertips. This setup not only enhances your workflow but also maintains enterprise-level security and compliance.

Benefits of using Microsoft Teams in manufacturing

Enhanced communication

In the manufacturing sector, clear communication is vital. Microsoft Teams enhances this by offering real-time messaging and video conferencing. You can create dedicated channels for different teams, ensuring that everyone stays informed and connected. This setup reduces misunderstandings and fosters a collaborative environment.

Streamlined processes

Microsoft Teams helps streamline processes by integrating with various tools and applications. You can automate repetitive tasks using Microsoft Power Automate, reducing manual errors and saving time. This automation allows you to focus on more critical tasks, improving overall efficiency. By using Teams, you transform isolated tasks into a cohesive team effort, driving productivity and innovation in manufacturing.

Real-Time Communication

In the fast-paced world of manufacturing, real-time communication is a game-changer. It ensures that everyone stays on the same page, reducing delays and misunderstandings. Microsoft Teams excels in this area, offering tools that make instant communication a breeze.

Chat and Messaging

Instant messaging features

With Microsoft Teams, you can send instant messages to your colleagues with ease. This feature allows you to quickly share updates, ask questions, or provide feedback. You don't have to wait for emails or phone calls. Everything happens in real-time, keeping the workflow smooth and efficient.

Group chat capabilities

Need to discuss a project with multiple team members? Microsoft Teams has you covered with its group chat capabilities. You can create dedicated channels for specific teams or projects. This setup ensures that all relevant information is in one place, making it easy for everyone to stay informed and contribute effectively.

Video Conferencing

Hosting virtual meetings

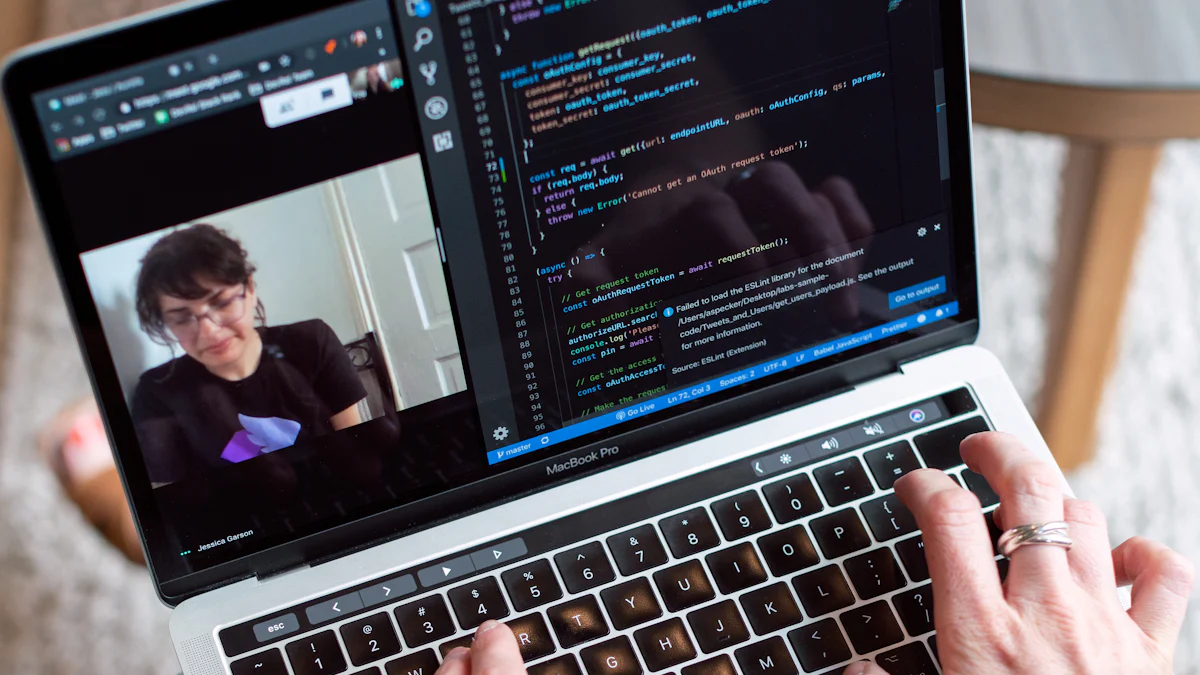

Virtual meetings have become a staple in modern manufacturing. With Microsoft Teams, you can host high-quality video conferences with just a few clicks. Whether you're discussing a new design or coordinating with suppliers, Teams provides a reliable platform for face-to-face interaction, no matter where you are.

Screen sharing and collaboration

Collaboration goes beyond just talking. Sometimes, you need to show your work. Microsoft Teams offers screen sharing features that let you present your ideas visually. You can share your screen during meetings, allowing others to see your documents, designs, or data in real-time. This feature enhances collaboration and ensures that everyone is on the same page.

Advanced Manufacturing Report highlights that transitioning from isolated tasks to a collective team effort boosts productivity and fosters creativity. By using tools like Microsoft Teams, you can dismantle silos and enhance communication, significantly improving your impact in the manufacturing sector.

Incorporating these real-time communication tools into your workflow can transform how your team collaborates. You can reduce delays, improve understanding, and ultimately drive better business outcomes.

Workflow Automation

Automating Repetitive Tasks

In manufacturing, repetitive tasks can consume a lot of your time and energy. Automating these tasks with Microsoft Power Automate can make a big difference. This tool helps you create workflows that handle routine processes without manual intervention.

Using Microsoft Power Automate

Microsoft Power Automate lets you automate tasks by creating workflows that connect different applications and services. You can set up triggers and actions to perform specific tasks automatically. For example, when you receive an email with an attachment, Power Automate can save it directly to a designated folder in SharePoint. This automation reduces the need for manual data entry and ensures that important information is always where you need it.

Examples of Automated Workflows

Here are some practical examples of how you can use Power Automate in manufacturing:

Inventory Management: Automatically update inventory levels when new shipments arrive.

Quality Control: Send alerts to quality assurance teams when a product fails inspection.

Order Processing: Generate invoices and send them to customers once an order is completed.

These workflows not only save time but also improve accuracy by minimizing human errors.

Improving Efficiency with Automation

Automation isn't just about saving time. It's about enhancing the overall efficiency of your operations. By automating repetitive tasks, you can focus on more strategic activities that drive growth and innovation.

Reducing Manual Errors

Manual processes often lead to errors, especially when dealing with large volumes of data. Automation helps eliminate these errors by ensuring consistency and accuracy. For instance, automated data entry reduces the risk of typos and incorrect information, leading to more reliable outcomes.

Saving Time and Resources

By automating tasks, you free up valuable time and resources. Your team can focus on more critical tasks that require human expertise and creativity. This shift not only boosts productivity but also enhances job satisfaction as employees engage in more meaningful work.

Real-life Power Automate Use Cases Across Industries highlight how automation improves operational efficiency and accuracy. By adopting similar strategies in manufacturing, you can streamline processes and enhance collaboration across teams.

Incorporating workflow automation into your manufacturing operations can transform how you work. It reduces the burden of repetitive tasks, minimizes errors, and allows you to allocate resources more effectively. Embrace automation to stay competitive and drive success in the ever-evolving manufacturing landscape.

Integration with Other Tools

Integrating Microsoft Teams with other tools can significantly enhance your manufacturing operations. By connecting with third-party applications, you can streamline processes and boost productivity.

Connecting with Third-Party Applications

Integration with ERP Systems

Microsoft Teams works seamlessly with ERP systems like Microsoft Dynamics. This integration reduces manual data entry and allows for real-time data sharing. You can connect CAD systems such as SOLIDWORKS 3D and Inventor with your ERP. This connection ensures that product data flows smoothly between design and production teams. It helps you maintain accuracy and efficiency in your operations.

Using Microsoft Teams with CAD Software

You can also integrate Microsoft Teams with CAD software like AutoCAD. This integration allows you to open and edit DWG files directly from OneDrive or SharePoint. By doing so, you can collaborate on designs without leaving the Teams environment. It simplifies the design process and keeps everyone on the same page.

Enhancing Productivity Through Integration

Seamless Data Sharing

With Microsoft Teams, you can achieve seamless data sharing across different platforms. This capability ensures that all team members have access to the latest information. Whether you're working on a design or managing inventory, you can share updates instantly. This transparency fosters better decision-making and collaboration.

Unified Communication Platform

Microsoft Teams serves as a unified communication platform. It brings together chat, video conferencing, and file sharing in one place. By integrating with other tools, you create a cohesive environment where everything you need is at your fingertips. This setup not only saves time but also enhances your team's ability to work together effectively.

Pro Tip: Use Microsoft Teams to create dedicated channels for specific projects. This organization keeps communication focused and relevant, improving overall productivity.

By leveraging these integrations, you can transform how your manufacturing teams collaborate. Microsoft Teams becomes more than just a communication tool; it becomes a central hub for all your operations.

Security and Compliance

In the manufacturing sector, safeguarding your data and ensuring compliance with industry standards is crucial. Microsoft Teams provides robust security and compliance features to help you achieve this.

Ensuring Data Security

Built-in Security Features

Microsoft Teams offers a range of built-in security features designed to protect your data. These include:

Data-Loss Prevention (DLP): This feature helps prevent sensitive information from being shared inadvertently. You can set up policies to detect and block the sharing of confidential data.

Information Barriers: These barriers prevent unauthorized communication between specific teams or individuals, ensuring that sensitive information remains secure.

eDiscovery and Legal Hold: These tools allow you to search for and preserve information for legal purposes, ensuring that you comply with regulatory requirements.

Microsoft Teams operates on the Microsoft 365 and Office 365 hyper-scale cloud, delivering enterprise-level security. It adheres to security best practices and procedures, including service-level security and customer controls.

Compliance with Industry Standards

Microsoft Teams meets various compliance standards, making it a reliable choice for manufacturing organizations. It complies with:

ISO 27001: An international standard for information security management systems.

HIPAA: Ensures the protection of sensitive patient health information.

SOC 2: Focuses on the security, availability, processing integrity, confidentiality, and privacy of customer data.

EU Model Clauses: Provides a framework for data protection in the European Union.

These compliance capabilities ensure that your organization meets industry standards and regulatory requirements.

Managing User Access and Permissions

Role-Based Access Control

Managing user access is essential for maintaining security within your organization. Microsoft Teams offers role-based access control, allowing you to assign specific permissions to users based on their roles. This approach ensures that employees have access only to the information they need to perform their duties.

Admin Roles: Assign administrative roles to manage settings and configurations.

User Roles: Define user roles to control access to specific channels and files.

By implementing role-based access control, you can minimize the risk of unauthorized access and data breaches.

Monitoring and Auditing

Monitoring and auditing are vital components of a robust security strategy. Microsoft Teams provides tools to help you track user activity and ensure compliance with security policies.

Audit Logs: These logs record user activities, such as file access and message exchanges, allowing you to monitor and review actions within Teams.

Microsoft Secure Score: This tool helps you assess your security posture and provides recommendations for improvement.

By regularly monitoring and auditing user activity, you can identify potential security threats and take proactive measures to address them.

Pro Tip: Regularly review your organization's security settings and update them as needed to ensure that your data remains protected.

Incorporating these security and compliance features into your manufacturing operations can help you safeguard sensitive information and meet industry standards. Microsoft Teams provides the tools you need to maintain a secure and compliant environment, allowing you to focus on driving innovation and growth.

Case Studies and Real-World Examples

Success stories from the manufacturing sector

Improved collaboration in production teams

In the manufacturing world, teamwork is everything. You can see this in action with companies that have embraced Microsoft Teams. For instance, a leading automotive manufacturer used Teams to connect its production teams across different locations. By creating dedicated channels for each team, they improved communication and reduced delays. Team members could share updates instantly, ensuring everyone stayed on the same page. This approach led to faster decision-making and a more cohesive work environment.

Enhanced project management

Project management can be a headache, but not when you have the right tools. A global electronics company found success by integrating Microsoft Teams into their project management processes. They used Teams to organize tasks, set deadlines, and track progress. With everything in one place, project managers had a clear view of what needed to be done. This clarity helped them allocate resources more effectively and meet project deadlines consistently. The result? Projects ran smoother, and teams felt more empowered.

Lessons learned and best practices

Overcoming implementation challenges

Implementing new technology can be daunting. You might face resistance from team members who are used to old ways of working. One common challenge is getting everyone on board with Microsoft Teams. To overcome this, start with training sessions. Show your team how Teams can make their jobs easier. Highlight features that address their specific pain points. Encourage them to explore the platform and ask questions. By providing support and guidance, you can ease the transition and foster a positive attitude towards change.

Maximizing the benefits of Microsoft Teams

To get the most out of Microsoft Teams, you need to use it strategically. Start by identifying the areas where Teams can add the most value. Is it in communication, project management, or data sharing? Once you know this, tailor your Teams setup to meet those needs. Create channels for specific projects or departments. Use integrations to connect Teams with other tools you use. Regularly review your setup and make adjustments as needed. By doing this, you ensure that Teams continues to support your goals and drive success in your manufacturing operations.

Encouraging Adoption

Strategies for Successful Implementation

Training and Support for Users

You want to make sure everyone feels comfortable using Microsoft Teams. Start by offering training sessions. These sessions can be hands-on workshops or online tutorials. Show your team how to use the features that will make their jobs easier. Encourage them to ask questions and explore the platform. Providing ongoing support is crucial. Set up a help desk or a dedicated channel in Teams where users can get assistance. This support helps build confidence and ensures a smooth transition.

Promoting a Collaborative Culture

Creating a collaborative culture is key to successful adoption. Encourage open communication and teamwork. You can do this by setting up channels for different projects or departments. This organization keeps conversations focused and relevant. Celebrate successes and share achievements within Teams. Recognizing contributions fosters a sense of community and motivates everyone to participate. By promoting a collaborative culture, you create an environment where everyone feels valued and engaged.

Measuring the Impact of Microsoft Teams

Key Performance Indicators

To understand the impact of Microsoft Teams, you need to track key performance indicators (KPIs). These KPIs might include metrics like the number of messages sent, meetings held, or files shared. You can also measure productivity improvements, such as reduced project timelines or increased output. By monitoring these indicators, you can see how Teams is enhancing collaboration and driving results.

Continuous Improvement and Feedback

Continuous improvement is essential for maximizing the benefits of Microsoft Teams. Encourage your team to provide feedback on their experiences. You can set up regular check-ins or surveys to gather insights. Use this feedback to make adjustments and improve the platform's effectiveness. For example, if users find certain features challenging, offer additional training or resources. By listening to your team and making improvements, you ensure that Microsoft Teams continues to meet your organization's needs.

Survey Results: A survey found that 98% of manufacturing organizations face challenges with data sharing among teams. By adopting Microsoft Teams and focusing on continuous improvement, you can overcome these challenges and enhance collaboration.

By implementing these strategies, you can encourage the adoption of Microsoft Teams in your manufacturing operations. Training, support, and a collaborative culture lay the foundation for success. Measuring impact and seeking feedback ensure that Teams remains a valuable tool for your organization.

Microsoft Teams transforms how you collaborate in manufacturing. It enhances communication, streamlines processes, and boosts productivity. You can enjoy real-time messaging, video conferencing, and seamless integration with other tools. These features make your work more efficient than relying on traditional email. By adopting Microsoft Teams, you create a unified platform that supports teamwork and innovation. Embrace this tool to stay competitive and drive future success in the manufacturing industry. The future looks promising as you continue to leverage technology for better collaboration and growth.

See Also

Strategies for Overcoming Microsoft Teams Management Obstacles

Achieving Remote Work Success with Microsoft Teams Mastery

Streamlining Processes with Microsoft Power Automate Automation

Revolutionizing Business Operations with Microsoft Power Apps